What is behind this name?

CARLY, French manufacturer founded in 1923, which will soon celebrate its 100 years of existence, became known in the small world of refrigeration component manufacturers in 1945 with his famous DCY filter-drier. This component will quickly become a reference in the field of filter-driers far beyond the borders of the hexagon (France !)

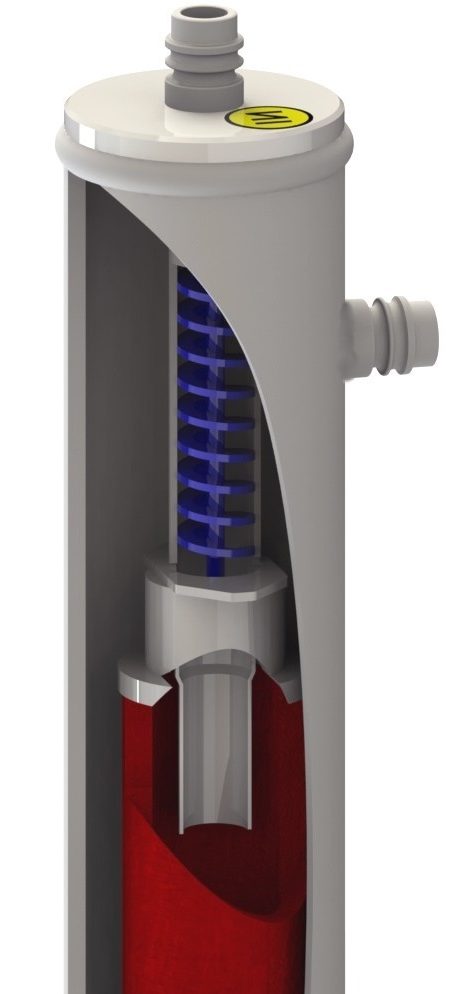

As early as in 1997, CARLY launched a breakthrough innovation in the field of oil circuit components: the TURBOIL oil separator, an original and highly efficient product.

This separation system, TURBOIL patented by CARLY, ensuring then at the time, the best oil / refrigerant separation rates through an original design: breaking speed, change of direction, centrifugation and coalescence phenomenon simultaneously.

Over the years, CARLY, has observed a significant increase in CO2 refrigeration plants. To participate to this market shift, CARLY developed a wide range of planet friendly components for this natural refrigerant :

• Sealed type filter-drier 64/140 bar

• Filters 64 bar

• Y filters 90 bar

• Discharge muffler 64/140 bar

• Replaceable core filter (driers ) 60/140 bar

• Check valves 90 bar

• Oil filters 64/140 bar

• Special oil for CO2 acidity tests

Following the field trips, discussions with the manufacturers and their customers, the CARLY scientific team notes that the efficiency of the transcritical CO2 separators strongly varies according to the load rates of the installations.

And it is known that these are likely to change significantly depending on the seasons or uses of the units.

Refrigerants such as CO2 require high pressure / high temperature systems to operate. These operating conditions – more extreme than in conventional systems – bring the refrigerant density closer to that of the oil in the compressor. That favors exchanges between the compressor oil on the one hand and the refrigerant on the other hand. The migration of very fine oil particles (size less than 1 micron) is then amplified at the discharge line, from the compressor oil to the refrigerant mass flow rate. The size, density and concentration of the fine oil particles in the refrigerant gas then vary according to the facilities and their use (charge rate).

This higher level of fine oil particles makes the separation of the oil more difficult with a CO 2 refrigerant than with a conventional refrigerant and for this reason the existing oil separating devices on the market have a number of disadvantages. In some cases a significant amount of fine oil particles remain mixed with the refrigerant gas, which tends to reduce the performance of the exchangers and to induce an undesirable oil consumption, and ultimately damage the installation. These fine particles of oil, present in the refrigerant gas, will in turn settle in the circuit of the installation until the flow in the installation (and consequently the velocity of the gas in the circuit ) increase again enough to naturally help these particles to the compressor.

The CARLY scientific team sees this problem as an opportunity to capitalize on its 20 years of experience in oil separation and to tackle this new challenge: how to develop a separator that would give “honest” results ie optimal, whatever the load rates of the installations!

The TURBOIL-P14 project was born within the CARLY teams

CARLY R & D then launched a program of in-depth studies on the complexity of the C02 hydrocarbon separation with the main objective of developing a tailor-made separation solution offering the highest quality standards over a very wide range of installations’ load rate. This intensive program of laboratory analyzes is then carried out by the CARLY R & D team on its pilot plants in its LISSIEU plant near LYON in order to comprehensively evaluate the performance of the main oil separators currently available on the national and international markets.

CARLY R & D was able to confirm the theory developed in the scientific literature (signature of the compressor) and document that

1) the level of fine oil particles in the refrigerant mass flow tends to be systematically higher in high pressure systems. CO2 than in conventional refrigeration systems and

2) its level varies with the refrigeration equipment load factor.

Thus, 20 years after the creation of TURBOIL, CARLY launches the TURBOIL-P14 for transcritical CO2 installations to track the fine particles of oils in CO2!

whose characteristics are as follows:

1. Superior efficiency

2. Integrity of results over a wide range of equipment load rates (integrity)

3. Maintenance-free / hermetic products

4. 140 bar 160 ° C

5. Vertical and horizontal mounting for certain models

6. Anti back wash system and muffler effect

To download the presentation flyer, click on the following link :