The clogging of the fins places high loads on the equipment to achieve the required temperatures. The compressor runs longer, its service life cycle is reduced; this can lead to its loss, the system uses more power, the coefficient of performance (COP) is significantly affected.

A 5°C increase in the temperature of condensation, on an installation in which heat exchangers are clogged, can lead to a reduction of 7% of the cooling capacity, an increase in the energy consumption of 10% and a net loss of 16% of the efficiency of the compressor. All these performance reductions are sources of rising operating costs.

Regular maintenance of the fins of the heat exchangers is therefore recommended to maintain energy efficiency and optimum performance of the installation, and extend the life of the equipment.

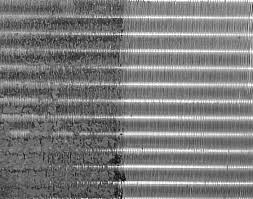

Before – After cleaning

CARLY has developed a dedicated cleaner / degreasing agent for aluminum micro-channel heat exchangers (MCHE), CARLYCLEAN-MC.

This highly efficient product removes dust, pollen, fat and viscous deposits.

Its neutral pH (7.0 – 8.5) preserves the natural aluminium oxide protective layer of the heat-exchangers.

CARLYCLEAN-MC is ready-for-use; it is applied by spraying directly on MCHE heat exchangers.

Non-foaming, it requires very little water for the rinsing phase.

CARLYCLEAN-MC is biodegradable and ecological; it is available in 500ml bottles or 5L and 25L cans.