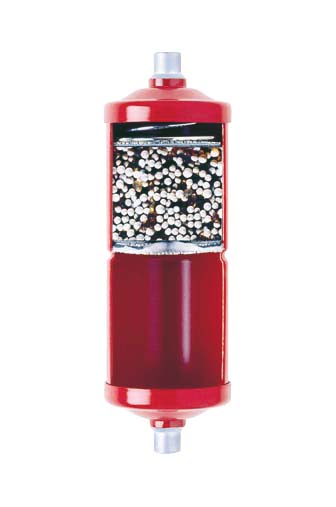

Refrigerant filtering and drying, and acid neutralization for refrigerating and air conditioning installation liquid lines.

The filter driers receivers provide a permanent reserve of dehydrated and filtered refrigerant, for a better supply of the expansion valve, whatever the operating conditions.

The filter drier receivers are particularly suited to low capacity installations that operate with a thermostatic pressure relief valve and that are equipped with an air-cooled condenser or a plate condenser.

Filter drier receivers fit perfectly within the heat pump systems.