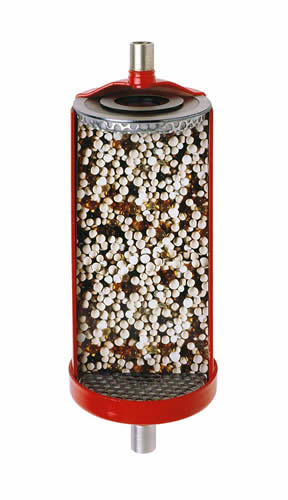

Refrigerant filtering, drying and acid neutralization for refrigerating and air conditioning installation liquid lines with change over in flow direction, including heat pumps.

Refrigerant filtering, drying and acid neutralization for refrigerating and air conditioning installation liquid lines with change over in flow direction, including heat pumps.

DDCY 082 | DDCY 082 S | DDCY 082 MMS | DDCY 083 | DDCY 083 S | DDCY 083 MMS | DDCY 084 | DDCY 084 S | DDCY 084 MMS | DDCY 163 | DDCY 163 S | DDCY 163 MMS | DDCY 164 | DDCY 164 S | DDCY 164 MMS | DDCY 165 | DDCY 165 S/MMS | DDCY 305 | DDCY 305 S/MMS | DDCY 307 S/MMS | DDCY 409 S | DDCY 411 S/MMS | DDCY 513 S | DDCY 517 S/MMS